The FPEG series of gas / water supply pipe production line is the new pipe production line developed by Friend Company after absorbing advanced technology from Europe, Use of energy-saving and efficient weight measurement of single-screw extruder, coordinate with the iNOEX gravity metering feeding system of Germany, realized extrusion speed and traction speed closed-loop control, high pipe yield, Effective control of the pipe wall thickness. Savings of 3% of the HDPE material. Adopt electromagnetic heating technology to heat the barrel and die can save electricity 30%, heating rate doubled.

Features of HDPE Pipe Extrusion Line:

1. High speed, high efficiency extrusion single screw extruder is specially designed for extruding PE etc. material, equipped with the lower noise, high speed and hard gear reducer. The Special grooved feeding bush with water cooling system results in increasing compression and filling factors. Specialised screw designs for high output, low melting temperature, good plasticization effection, lower energy consumption.

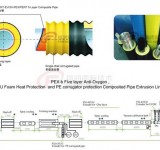

2. Spiral diffluence type extrusion die is specially designed for PE extrusion. Unique design of low-pressure inclined flow passage spiral/lattice basket diehead, ensures low temperature and high plasticizing extrusion of PE pipes; Special designed die core spiral temperature control, ensures the performance of PE pipes; Multi-layer co-extrusion die offers the advantages of low cost and flexibility of layer structure with different material. it features in easy adjustment and even extrusion, ensures that melting pressure and flux are uniformity, the surface of pipe is smooth and shapely.

3. Pipe marking line is extruded by smaller single screw extruder through the composited extrusion die.

4. Vacuum calibration water tank: it is equipped with two-stage vacuum system(for large diameter)advanced water recycle & high pressure cooling system, vacuum degree adjustment device and accurate water level & water temperature automatical control system. The accurate stannum bronze calibratation sleeve ensures fast cooling speed and molding of pipe. Its material is stainless steel.

5. Spray cooling water tank: Long cooling unit ensures high efficiency cooling, Unique pipeline design shorten cooling length, its material is stainless steel.

5. Haul-off unit: special integral transmission unit avoids asynchrony of individual transmission, Various control method ensures more flexible & accurate orientation, Accurate pressure regulating system makes hauling power adjustable. It has unique structure & flexible operation, its speed can be adjusted by motor inverter.

7. Cutting unit: Full-hydraulic design of cutting unit ensures flexible pressure in state of cutting pipes, Flexible adjust for saw position & cutting depth, Unique power input system ensures high reliability of planetary unit, With ultra silent & enforced sucking system, Unique non-scrap cutting unit enusre clean cutting section for 16mm to 315mm pipe.

8. Control system: Adopts the one of the most advanced plastic extrusion machinery control systems----PLC. It can ensure much higher quality extrusion, PLC system ensures high speed and convenient internet function that much more accurate and flexible control, intelligentized control order make the operation more simple.